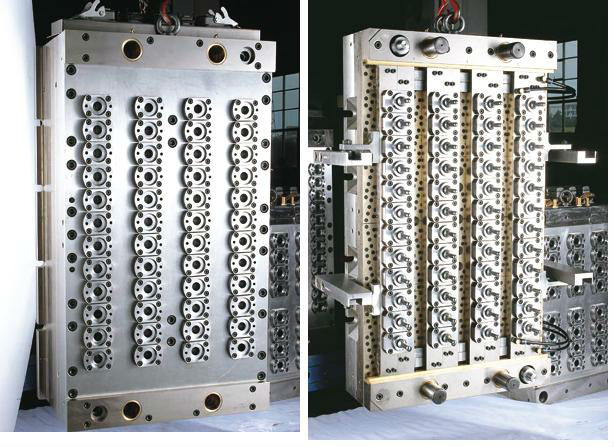

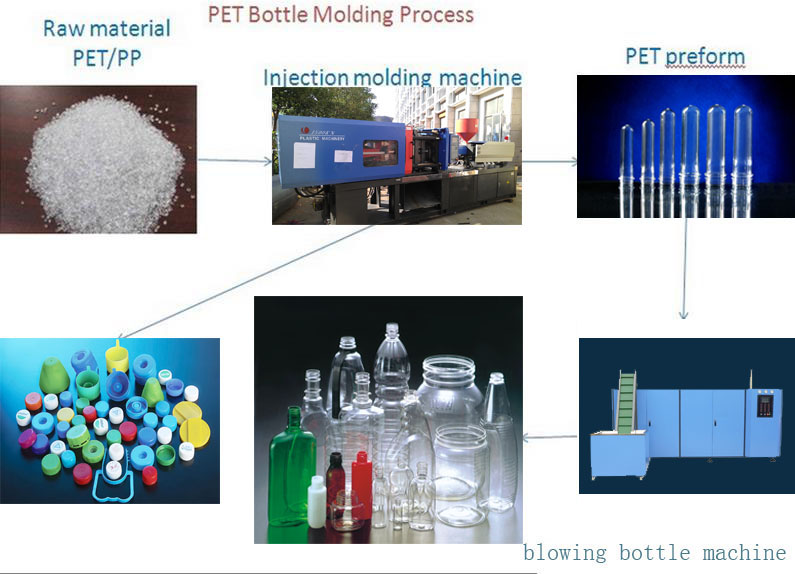

Moule d'injection de préforme pour animaux de compagnie

Informations de base

Modèle: 2-72

Description du produit

ProductivitéFast cycling en raison de circuits de refroidissement spécialement conçus

Des capteurs d'éjection de pièce qui surveillent le transfert de préforme à la plaque de décollage, améliorant le temps de cycle

Composants de moules interchangeables standard, pièces de rechange disponibles dans les 24 heures

Fiabilité

Design robuste pour une longue vie

Des cônes auxiliaires qui réduisent l'usure du moule en pré-alignant les moitiés du moule avant l'enclenchement des billes de col

Les cames à rouleaux actionnent à la fois les actions d'ouverture et de fermeture sur les divisions de fil

Qualité des pièces

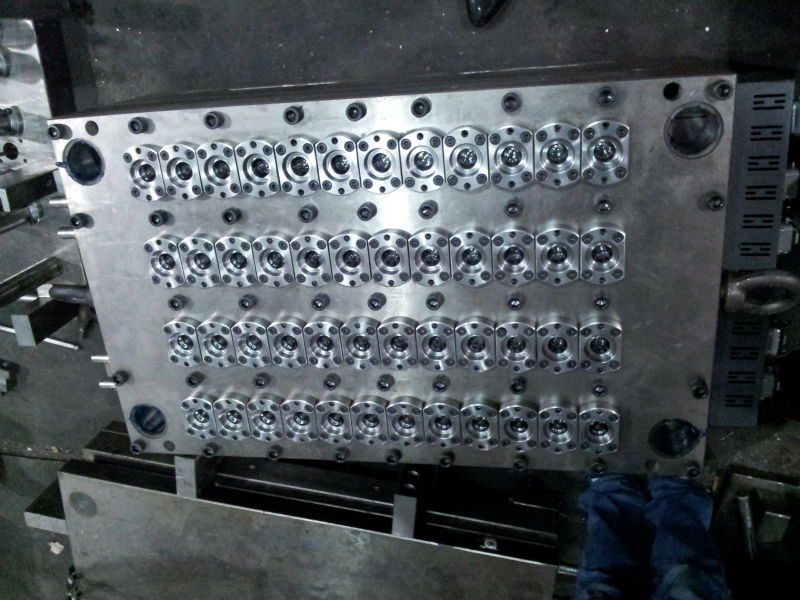

Le poids et la variation dimensionnelle de la cavité à la cavité les plus bas en raison des meilleures machines et procédés de fabrication

Tuyaux d'eau qui sont assemblés au bas du moule de préforme du canal chaud, élimination du potentiel de marques d'eau sur les préformes

PET Preform Mould Main Components Specification and Advantages | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main component |

Specification and Advantages |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Core |

2316 steel from Sweden |

high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Neck |

S136 steel from Sweden, HRC >60, International standard screw neck |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cavity |

2316 steel from Sweden Each cavity have an independent temperature controller Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Body |

P20 Steel material from Germany |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot runner plate |

2344 Steel material from Germany

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slider Plate |

wear-resistant copper |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

specially designed cooling circuits |

Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot runner design |

make sure the high quality of preform products. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heater |

Anole Germany |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

valve gated design with Automatic drop |

each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precessed by high presion CNC machine and numerical control loathe machine |

Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

DONNÉES MOULES

Groupes de Produits : Moule de préforme Premium Related Products autres produits

Produits phares Machine de moulage par injection à main 200t / machine à moulage par injection de bouteilleMoule en plastique à injection, moule en plastique, moule de préformeMoule à injection / moule en plastique préformé de 28 mmMachine de remplissage automatique 5 gallons en PETSystème d'osmose inverseConception de bouteilleMoule à bouchon de bouteille à 48 cavitésMachine de soufflage semi-automatique à deux cavitésMachine de moulage par soufflage entièrement automatique (6 cavités) Surpasse d'usineMachine de moulage par injection de tuyau de pvc 438tonsPrix de la machine à moulage par injection plastiqueMachine à moulage par injection prix HDX2000 IIMACHINE DE MOULAGE D'INJECTION DE BOUTEILLE DE PET PREFORME HDX208PET POUR PETIT VOLUMEMoule préformée pour animaux domestiques de haute qualitéHDJS128 machine de fabrication de seringue à usage unique de haute qualitéMachine de moulage par injection de rasoir | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||